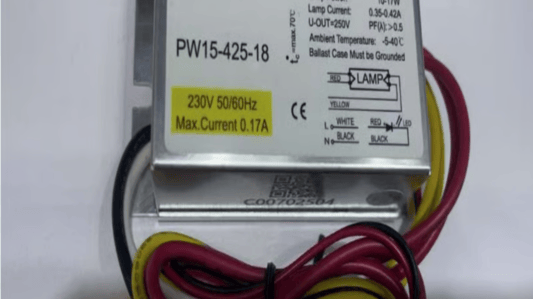

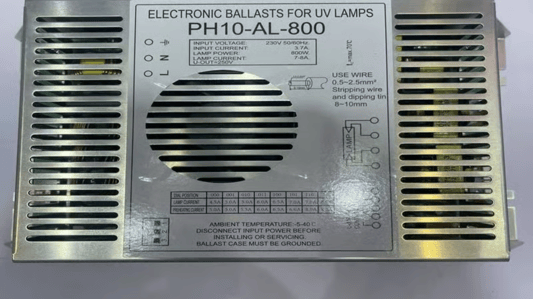

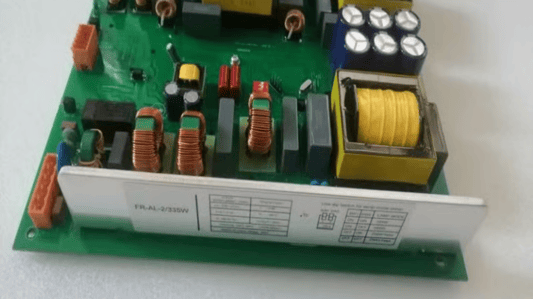

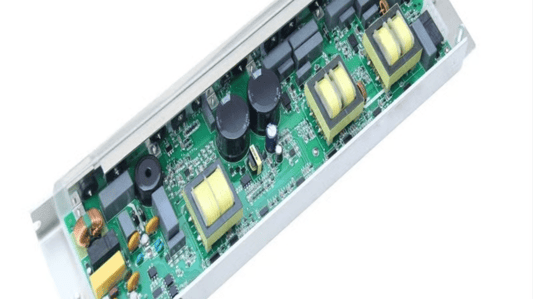

Introduction to Uv ballast PW15-425-18The UV ballast PW15-425-18 is a crucial component designed to regulate electrical current in ultraviolet (UV) lighting systems. This ballast specifically supports UV lamps, ensuring optimal performance and longevity. Its engineering caters to specialized industrial and commercial applications requiring precise control of UV light for disinfection, curing, and other processes.Technical Specifications of the UV Ballast PW15-425-18The PW15-425-18 UV ballast operates at 425 watts and is tailored to fit 18-inch UV lamp configurations. It delivers steady current and voltage, ensuring the UV lamps maintain consistent brightness and efficiency. With advanced electronic components, this ballast offers improved power factors and reduced energy losses compared to traditional magnetic ballasts.Energy Efficiency and Environmental BenefitsOne of the defining features of the UV ballast PW15-425-18 is its energy efficiency. This ballast consumes less power while providing stable illumination, contributing to significant energy savings over time. Additionally, the ballast’s design supports environmentally responsible operations by reducing heat emissions and minimizing electrical waste.Applications in Water and Air PurificationThe UV ballast PW15-425-18 is widely deployed in water and air purification systems. It powers UV lamps that eliminate harmful microorganisms by disrupting their DNA. Industries such as municipal water treatment, HVAC air sterilization, and medical sanitation rely on this ballast to maintain effective UV disinfecting processes.Role in Industrial UV Curing ProcessesIn industrial settings, UV curing applications benefit greatly from the reliable performance of the PW15-425-18 ballast. It supports UV lamps that cure coatings, adhesives, and inks swiftly and uniformly. This enhances production speed and quality consistency, making it indispensable in manufacturing lines involving rapid drying or hardening.Compatibility and Installation ConsiderationsCompatibility with various UV lamp types makes the PW15-425-18 ballast versatile. It is primarily matched with 18-inch high-intensity UV lamps but can be integrated into broader UV systems with appropriate modifications. Installation requires adherence to electrical safety standards to ensure optimal ballast performance and reliability.Durability and Maintenance of UV Ballast PW15-425-18Constructed with robust materials and advanced circuitry, the PW15-425-18 ballast is designed for long service life and durability in demanding environments. Minimal maintenance is required, mostly revolving around periodic inspections and ensuring that electrical connections remain secure and free of corrosion.Impact on UV Lamp LifespanUsing the correct ballast like the PW15-425-18 significantly affects the longevity of UV lamps. It prevents electrical fluctuations that can stress lamp components and cause premature failure. Consistent voltage regulation promotes stable ignition and sustained output, thus extending the functional life of UV lamps.Safety Features Integrated in the BallastSafety is a priority in the design of the UV ballast PW15-425-18. Features include overload protection, thermal cut-offs, and short circuit prevention. These safeguards protect both the ballast and the UV lamps from electrical damage, reducing the risk of fire hazards and electrical shock during operation.Market Availability and Purchasing TipsUV ballast PW15-425-18 units are available through specialized industrial suppliers and authorized dealers. When purchasing, it’s important to verify the ballast’s compatibility with the specific UV lamp model, check warranty terms, and ensure that the product meets local electrical standards and certifications for safe use.Quote Inquirycontact us